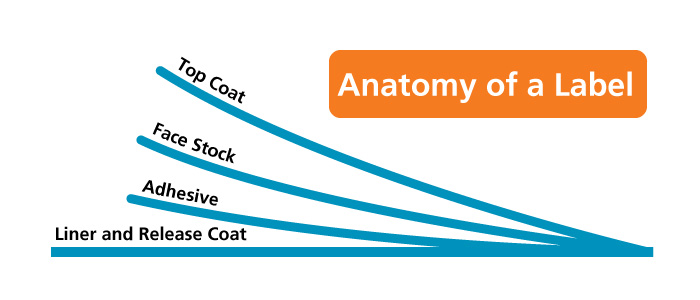

Look around you. Practically everything you see either once had a label on it or was in a container with a label on it. These common labels are designed to stick to surfaces by applying pressure, therefore given the term pressure sensitive labels. To look into the construction of pressure sensitive labels, you can see the composition of layers that each serve a different purpose:

Liner and Release Coat

The labels stick on to something called the liner, which is simply backing paper. A release coat is applied on the liner and needed in order to counter the adhesive.

Adhesive

Labels stick on to products based on the adhesive used. Adhesive formulations vary widely, and the type used is based on the application. They can include (but not limited to):

- Environmental factors (wet, dry, hot, cold)

- Texture of the product (uneven or smooth surfaces)

- Lifespan of label (permanent or removable)

Face Stock

The face stock is the side of the label that you visibly see. Paper is most commonly used; however, other varieties can include films, foils, and other types.

Top Coat

Some labels include a top coat for enhancement. This top coat can serve a variety of purpose including protection from environmental factors, give label a more sophisticated look, allow for better printing for date or lot coding, and many more.

You can improve workplace productivity and save your company money by incorporating our label dispensers into your existing production lines. Below, we have provided information about the construction of labels.

Explore our label dispensers here.

Label Orientation Chart here.